Verizon Technical Writing Internship

I had my internship with Verizon in the summer of 2022, working in marketing for one of their business acquisitions, IncubedIT. I came into the internship with little knowledge of marketing or their product, Autonomous Mobile Robots (AMRs), but with quick learning and consultation with SMEs, I was able to create a technical eBook, blog articles, interviews, white papers, webinar scripts, social media posts, promotional emails, sales decks, marketing communications, etc. Below is some of the content I wrote for them.

Picture a warehouse with racks and shelves packed full of merchandise. Employees drive forklifts or use pallet jacks to move goods as an integral part of their job. This is a pretty standard operation, but there are risks: the pallets can weigh up to hundreds of pounds, potentially falling onto employees and injuring them. What if there was another way to transport merchandise around warehouses and facilities without risking people’s safety?

Thanks to advances in robotics technology, now there is: Autonomous Mobile Robots (AMRs). AMRs are transforming the future of how warehouses are run. Sometimes, these robots can help fill in jobs that are too dangerous or hard for humans. They’re also perfect for repetitive and monotonous jobs, but flexible enough to cope with changing, dynamic environments and more complex tasks.

What are Autonomous Mobile Robots (AMRs)?

AMRs are robots equipped with sensors and processors that work in tandem with intelligent software to autonomously perform tasks without needing a set path or human supervision.

To imagine AMRs better, think of the robotic ground vacuums found in many households. (This isn’t a perfect comparison — but in many ways these robotic vacuums are very similar to AMRs.) Newer generations of robotic vacuums can navigate the floor of a house, avoid obstacles, and perform a job.

But now picture a robot ten to a hundred times larger, with industrial-grade sensors and safety features, and with different models designed to perform a variety of tasks. They may be carrying containers, lifting pallets, shelving merchandise, scanning stored products, and more. They have many applications, including pick assist, material handling equipment, and infrastructure replacement.

Now imagine putting five, ten — even a hundred of these robots to work in an industrial facility. With minds coordinated over one network, AMRs are able to do a lot more than just vacuum the floors. These robots are here to assist on the job for safe, efficient everyday operations of many kinds.

The incubed IT software solution

Here at incubed IT, a Verizon company, we’re excited about AMRs because of what they can do for you and your business. incubed IT provides a software solution for autonomous mobile robots, bringing together intelligent robotic control and extensive fleet orchestration.

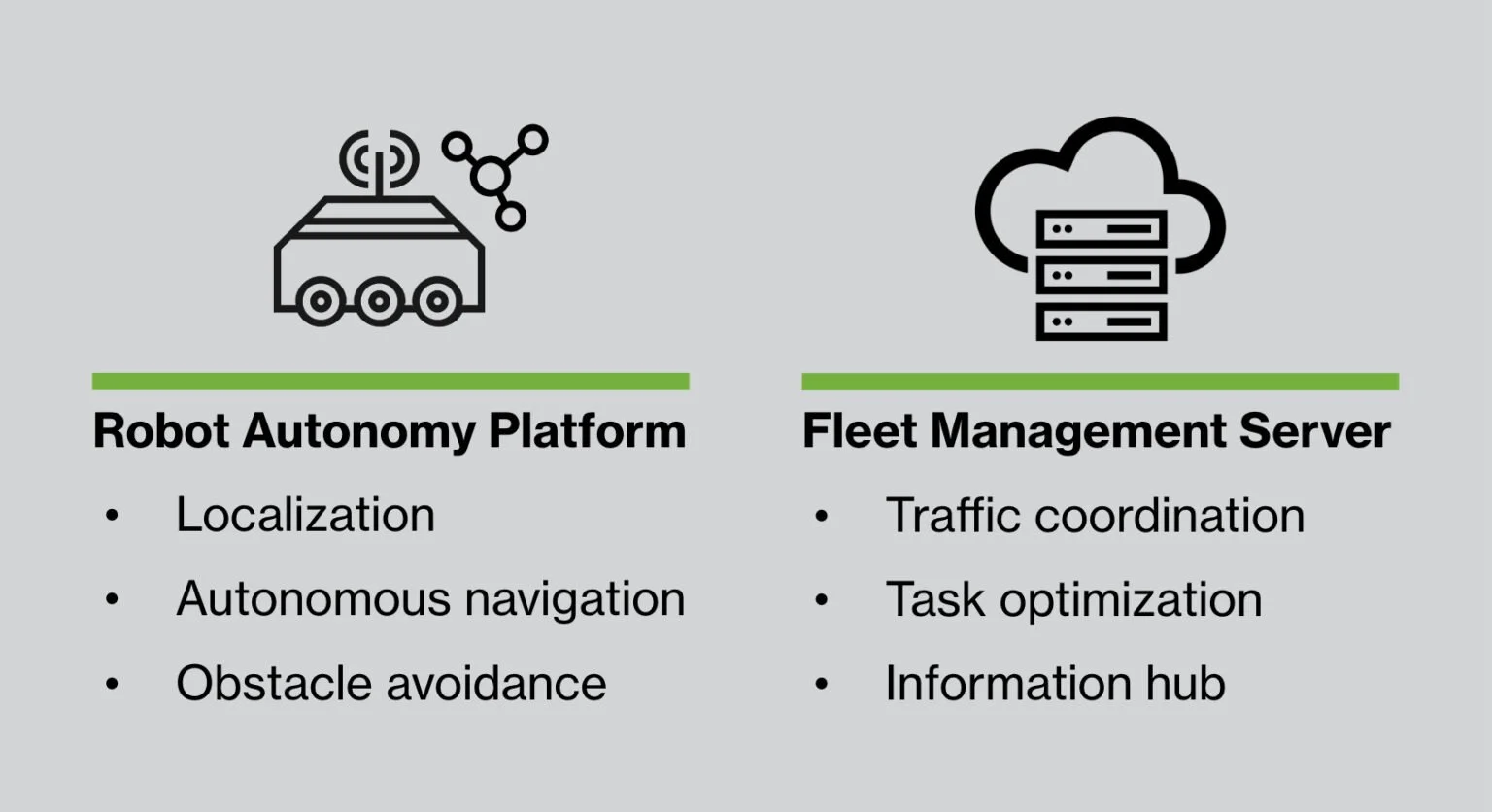

incubed IT offers software that works with AMRs so they can seamlessly complete their jobs. The first part of the incubed IT solution is the Robot Autonomy Platform. This onboard software is the “brains” of the robot; it utilizes localization and autonomous navigation.

Localization enables the robot to understand where it is based on sensor information and networked computing.

Autonomous navigation allows it to choose the best path from point A to B intelligently.

The AMRs use obstacle avoidance, which means they can determine what to do if, for example, a person or another robot comes into their path. The Robot Autonomy Platform helps the AMR assess the situation through its sensors and choose the best route for moving around the obstacle. That means you will have a more robust transport system in your facility.

Additionally, the decentralized intelligence of the robots allows reduction of the configuration of the system, since the robots know how to cope with different situations. Less configuration means less work and reduced complexity.

The second part of the incubed IT solution is the Fleet Management Server, an integrated system for managing and coordinating fleets of mobile robots. The server connects individual AMRs to all the other robots that the facility owns. The server helps assign and optimize tasks to robots without the hassle of manually trying to coordinate what robots should do.

The Fleet Management Server also helps coordinate driving behavior like a traffic advisor. Traffic areas can be reserved and locked, letting the robot know not to go into certain areas. All software services are built to be cloud-ready, allowing you to access the server on-premise and in any cloud environment. Workers can manage the robots in the facility through this server with minimal effort.

If you want to get started with AMRs operated by incubed IT software, fortunately you won’t need to go through the hassle of trying to set it all up on your own — incubed IT will be there for you. Along with our AMR partners, we’ll help you set up your own fleet of AMRs with minimal complications.

We will also train you to manage and control your AMRs with the incubed IT platform, so you can seamlessly transition from the setup to running your fleet on the job.

Why choose incubed IT for your AMR needs?

There are several benefits of working with incubed IT for your AMR needs.

Our software solution provides intelligent robotic control so that the AMRs work efficiently and seamlessly.

It’s easy to expand your fleet of AMRs — our software can easily integrate additional robots so you can smoothly operate your expanded fleet with minimal complications.

The software also accounts for safety, allowing you to configure traffic areas and no-go zones, plus automatic obstacle avoidance and rerouting to adjust how your fleet behaves.

Our software is convenient for everyday use. You can easily implement and configure your setup via a user-friendly web-based interface for an intuitive overview of all your AMRs in your facility.

incubed IT would love to help you create a safer and more efficient workplace by starting your own AMR fleet and joining the future of businesses today.

How can you learn more?

Do you want to learn more about AMRs or incubed IT? Contact us at office@incubedit.com with your questions.

We’ve all been there: you log onto your favorite online store and impulsively order something — clothing, a game, food — that you may or may not regret when you receive the package in the next few days. But don’t you wonder how you’re able to get such a random assortment of items so quickly?

There are a lot of factors that play into the complex logistics of online ordering and delivery. But what you may not realize is that mobile robotics often play a huge part in this process.

What kind of robots help with online orders?

Autonomous Mobile Robots (AMRs) are robots that use sensors, artificial intelligence, and software — like that offered by incubed IT, a Verizon company — to intelligently move around and avoid obstacles without needing a person to oversee them. They can be used for many different jobs: carrying containers, inspecting facilities, moving pallets, scanning labels, and much more. One of these applications is assisting with picking orders in a timely manner so people receive their packages quickly.

According to Timothy Christianson, Principal Solutions Architect at Verizon Robotics, a typical human picks 50 items per hour with the top pickers picking around 80-100 per hour. He has observed that a fully-automated AMR picking solution can complete up to two times that rate. And he has seen hybrid goods-to-person (GTP) systems that can augment workers for rates up to 500–600 pieces per hour.

AMRs are very helpful in the realm of online orders. Today, in order to streamline order fulfillment processes, companies can rely on AMRs to assist human pickers. This is essential to increasing global retail sales volumes and same-day deliveries.

Why are AMRs important in order picking?

To delve deeper into just how helpful AMRs can be in order picking, let’s look at a study from the European Journal of Operational Research about order batching and batch sequencing in an AMR-assisted picker-to-parts system.

According to the study, order picking is laborious and expensive for warehouse operations, taking up to 65% of total warehouse operating costs. Being late on deliveries results in customer dissatisfaction and increased labor costs for the warehouse. Order picking is therefore crucial for the competitiveness of a supply chain.

The study estimates that 80% of all order picking systems in Western Europe follow the traditional picker-to-parts setup, where people walk around the facility to pick up the items for an order. This walking time accounts for 50% and more of total order picking time.

The team studied a warehouse divided into zones, each with one human order picker and several AMRs assigned to it. Each zone was given a set of customer orders with due dates for when they need to be collected. The worker brought customer orders to the picking area, and AMRs were responsible for transporting batches of orders from the picking area to the depot.

The study found a series of advantages to AMR-assisted order picking:

It reduces the amount of walking a worker must do and increases the amount of orders completed. With the addition of AMRs, order pickers are able to continue picking out items for orders without needing to leave and deposit items elsewhere. AMRs are able to save time by taking on the delivery part of the worker’s job. With the use of AMRs, a reduction of about 20% of travel distance can be achieved, meaning that more orders can be completed in less time.

It’s relatively easy to implement an AMR-assisted order picking system into existing warehouse operations without the need for heavy changes. Compared to other solutions, which can be infrastructure-intensive, AMRs often require little change to existing environments. (And with the incubed IT software solution for AMRs, we can help you set up and optimize AMR operations in your facility.)

AMRs used in warehouses and industrial facilities are highly reliable. Even if one AMR stops working, the other AMRs are not affected and can intelligently route around it as they continue their work.

AMRs are highly flexible compared to other systems such as conveyors. If a business needs to redesign their facility’s floor layout, AMRs can quickly adapt to the new changes and carry on with their jobs.

While AMRs can be optimal for order-picking, they may also be able to carry out other tasks around the facility, and can be automatically reassigned to other tasks as demand shifts throughout a workday.

Order-picking is an important job that affects millions of people’s lives every day, and AMRs are an important aspect of this industry. If your business is looking into AMRs for your facility, contact us at office@incubedit.com to ask questions or set up a demo.